Home > Manufacturing

Award winning, advanced manufacturing plants

Engine components, engines, gensets, and tractors, made with advanced manufacturing

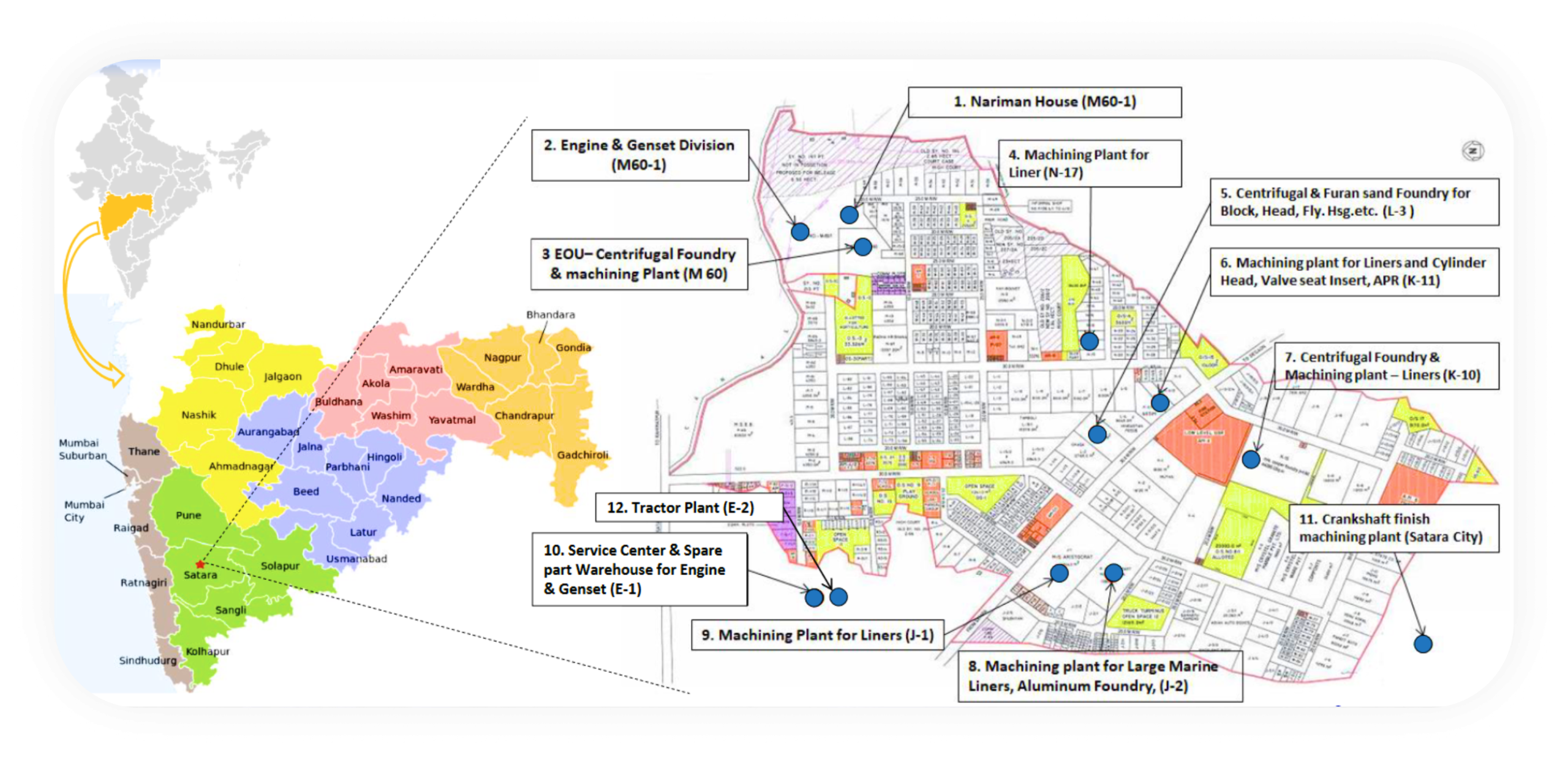

Cooper Corp. has 13 state-of-the art manufacturing plants in Satara, (Maharashtra, India) making diverse products from engine components, engines, gensets, and tractors catering to customers worldwide.

We take immense pride in our highly advanced, TS, ISO-certified, award winning manufacturing facilities producing the finest quality products.

We take immense pride in our highly advanced, TS, ISO-certified, award winning manufacturing facilities producing the finest quality products.

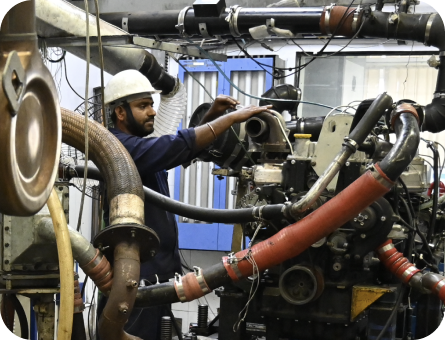

Our manufacturing plants are equipped with precision casting, machining, and honing facilities and all critical machines are imported from renowned global manufacturers such as Junker, WMW, Fanuc, Makino, Mazak, Doosan , Zaiss , Mitutoyo and Nagel.

The machining lines are highly productive and are equipped with automations through robotics & gantry system from Fanuc , Kuka , Gudel, Felsomat etc.

Our plants are continuously updated, meeting the latest global standards and customer specifications. The production process is constantly monitored to ensure consistency in quality. We use high-performance machine tools in each phase of the process to achieve the desired surface finish through optimised machining operations.

Key Highlights

13 World-class

Plants

in Satara spread over

7.46 hectare

100+

Products

Manufactured

120

Metric Ton

Melting Capacity

100

Million+

In production per year

Diversified Production Facilities

Centrifugal Production

Mould Making

Machine Lines with Pick

and Place by Robots

Crankshaft Production

Advanced Ptoduction (Brazing Machine, Laser Hardening Machine, Honing Machine)

Stress Relieving

Phosphating

and

Power Coating

Aluminium – Pressure Die Casting

Engine and Genset

Tractor

The heart of every engine –

Cooper Engine Components

Equipped with state-of-the-art plant and machinery, we at Cooper Corp possess the technology and expertise that makes us one of the biggest engine components manufacturers in India. We make the entire range of cylinder liners for automobiles, tractors and stationary industrial applications as per international standards.

Sought after for its precision and quality, Cooper Corp is among the top three manufacturers of cylinder liners worldwide and a trusted source for crankshaft machining for many reputed OEMs.

The company’s capabilities in components also include Centrifugal Casting, Sand Casting, Pressure Die Casting, CNC & Robotic Machining Lines, Crankshaft Machining, Engineering, Product and Material Development.

Apart from cylinder liners and crankshafts, our component portfolio consists of cylinder heads and cylinder blocks, valve seat inserts, flywheels and pulleys, crankcase insert, aluminum parts, pistons and anti-polishing ring. Our futuristic infrastructure supports our capabilities and progressive goals for delivering the highest quality components to our clients’ world over.

Testing Facilities

Each product from Cooper undergoes stringent levels of quality testing. Our well-equipped laboratory has a trained workforce that conducts Chemical and Microstructure analyses, Tensile Strength inspection, Elongation tests, Modulus of Elasticity examinations and other maintenance processes – from quality control to assurance.

Our in-house facilities for regular testing and analysis of parts also includes Emission Spectrometer (for analysis of chemical composition), Hardness Testing machines (BHN & HRB) and Metallurgical Microscopes with CCTV camera for evaluation of microstructure.

Testing and analysis are also carried out at NABL-approved laboratories for third-party evaluation of tensile strength and modulus of elasticity.

CMM – Zeiss/Mitutoyo

Hardness Testing

Impact Testing

Tensile Testing

Eddy Current Testing

Ultrasonic Testing

Auto Gauging System

Radioactive Radiation Detection

Profile Projector

Spectro Analyzer

Image analyser

Millipore Analysis

Microscope

13 State-of-the Art Manufacturing

Units in Satara