Engine Componenets

The heart of every engine –

Cooper Engine Components

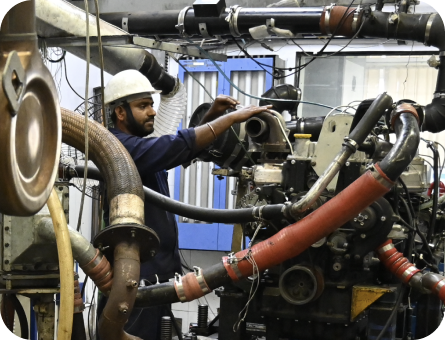

Equipped with state-of-the-art plant and machinery, we at Cooper Corp possess the technology and expertise that makes us one of the biggest engine components manufacturers in India. We make the entire range of cylinder liners for automobiles, tractors and stationary industrial applications as per international standards.

Assured Quality Standards

All plants are certified with ISO/TS-16948:2009 & ISO-9001:2008 for quality management systems. We’re also EMS ISO-14000 certified. All quality certification is done by TUV SUD, IATF/ NABCB accredited certification body.

Lloyds approval & ABS approval: Our foundry plants are approved by Lloyds & ABS for casting manufacturing process, casting capacities from 5 kilogram to 2.5-metre cylinder liners. This incidentally is also a key requirement of approval process by marine engines.

Cooper Corp has consistently ranked high on customer satisfaction across surveys and has bagged many Customer Appreciation Awards over the years.

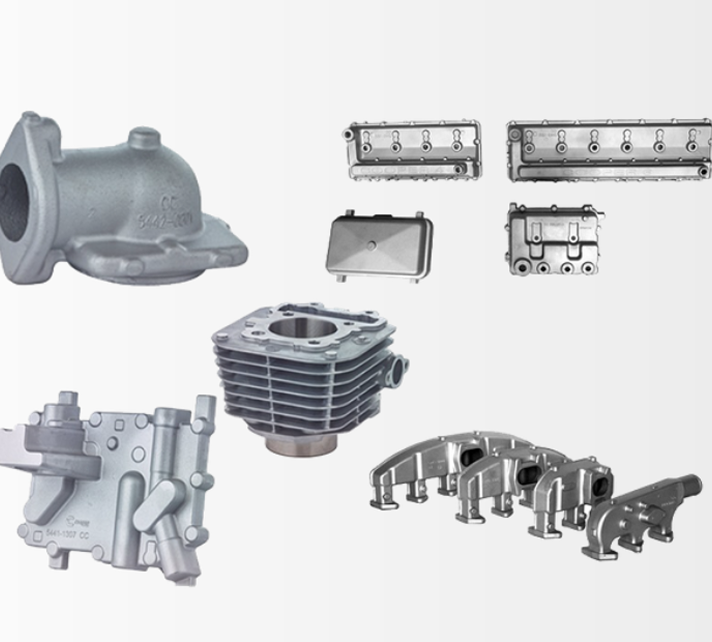

Engine Components

Cooper is among the top three manufacturers of cylinder liners in India and a sought after source globally for crankshaft machining for Cummins US. Presently, Cooper has the unique distinction of supplying 100% of the export requirements of crankshafts to Cummins India Ltd., for use in Engines for Gensets and Earth-moving Machinery. Apart from Cylinder Liners and crankshafts, our component portfolio consists of Cylinder heads and Cylinder Blocks, Valve Seat Inserts, Flywheels and Pulleys, Crankcase Insert, Aluminium Parts, Pistons, Anti Polishing Ring.

Cylinder Liners

Spiny Liners

Thread Liners

HHP Liner

Big Liners

Valve Seats

Control Arm

Centrifugal Flywheel

HHP Lead

Cylinder Head

Cylinder Head 7.8L Engine

Cylinder Block for 1.2L

Anti Polishing Ring

HHP Piston

Cylinder Head 215+

Crankshaft

Heavy Components

Cylinder Block for 1500 HP Engine | Cylinder Block for 3.5L | Cylinder Block for 4.5L | Cylinder Block for 7.8L

Aluminium

Raw Material Alloys

HPDC – ADC 12 | LPDC – AI Si9 Cu3 (Fe) | GDC – AI Si9 Cu3 (Fe)

Aluminium Products

Rocket Cover | Intake Manifold | Housing | Gas Mixer | Aluminium Blocks

Explore Cooper Engine Componenets

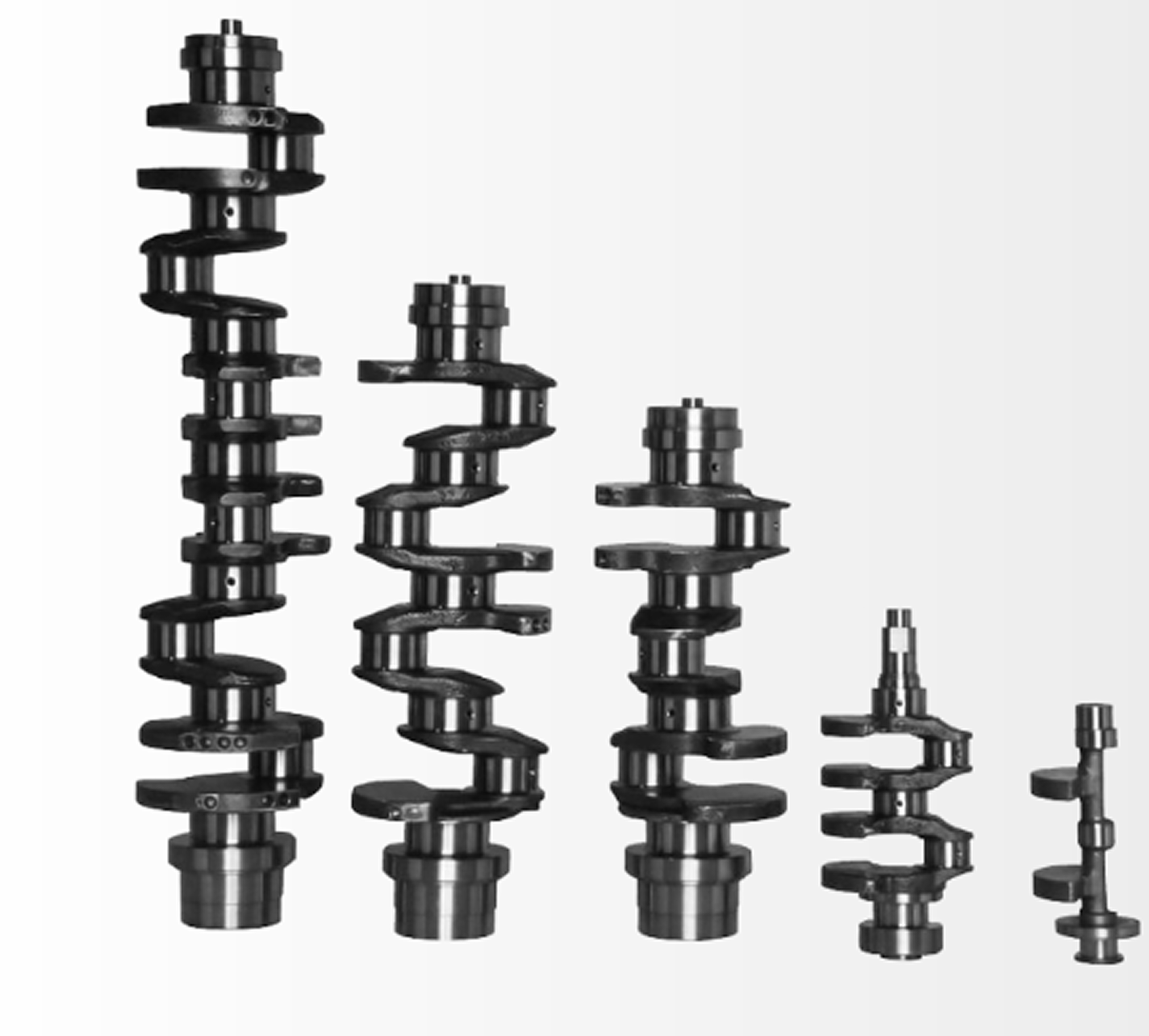

The crankshafts are mainly manufactured by forging and spheroidising cast iron which is then machined through a very critical machining process. Cooper Corp ranks amongst the most experienced crankshaft manufacturers in India. These are designed based on the engine requirements which range from single to multiple cylinders. The pin diameter, main diameter, throw, pin and main width, and surface finishes are the critical components of a crankshaft. All crankshafts are induction hardened to main and pin diameter at 50~60 HRC

The Cooper Corporation is equipped with casting and other support facilities for manufacturing S.G. Iron Crankshafts. We use CNC Sander and Super-finishing Machine in our production process along with Induction Hardening Machine.

Cooper supplies crankshafts within India and around the world to an elite client base for automotive, marine and industrial applications. Recently the machined crankshafts made by Cooper were used by ISRO in the High Pressure Compressor for the liquefaction of hydrogen for Chandrayaan 3- India’s mission to the moon.

The liners are typically manufactured from cast iron in grades FG20 to FG55.

Inside diameter and its surface finish are the most critical parameters of a cylinder liner, and Cooper Corporation specialises in manufacturing them through a highly evolved stringent process. Essential performance properties of cylinder liner are wear and tear, anti-galling and extended life.

We now produce 8,000 tonnes of cylinder liners per month, and are among the Top Three Manufacturers of cylinder liners in India.

Cooper R&D team has has developed centrifugally cast cylinder liners manufactured with our own formula alloy cast iron which gives it phenomenal wear and corrosion resistance with optimal durability and resistance to scuffing.

All cylinder liners are finely ground and bore machined to the last micron for that unique ‘Cooper Grip’ finish.

Cooper cylinder liners are used in locomotives, earth-moving equipment, the automotive industry, tractors, Oil and Gas industries, power plants, gensets and various other industrial applications

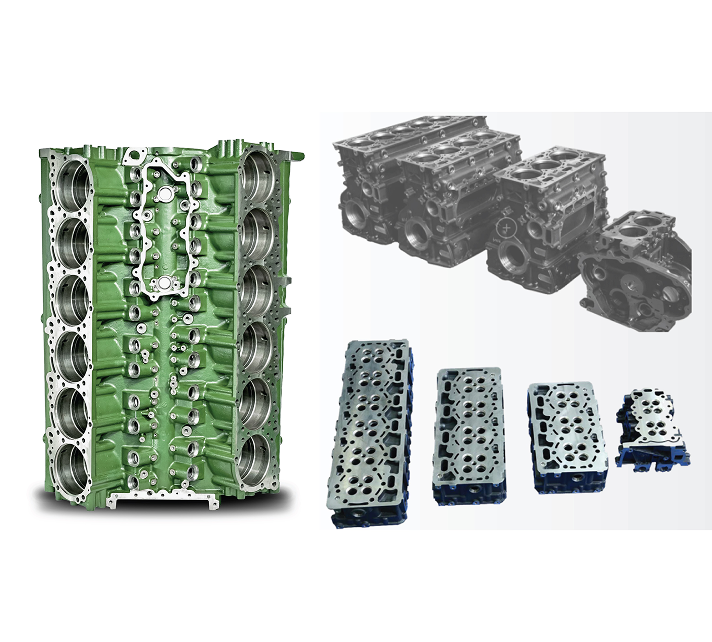

We are a leading manufacturer of cylinder heads and cylinder blocks producing both modular or integrated ones which are designed as per the requirement of the engine.

The most critical part namely valve seat guide is manufactured with special tools & the machining process. The cylinder heads are manufactured in cast iron & compacted graphite iron. The cylinder heads range from single cylinder to multiple cylinders.

The cylinder blocs – the main part of an engine are designed based on the requirements and manufactured for single cylinder as well as multiple cylinders, using cast iron grades and COMPACTED GRAPHITE IRON. For critical parameters such as crank shaft bore, camshaft bore, cylinder liner bore, HLA bore, flawless quality is ensured using specialised equipment & tooling.

At Cooper Corporation we produce all types of Cylinder Heads and Cylinder Blocks to exact customer specifications on an imported moulding line with strict controls on the core to ensure leak proof Cylinder Heads with clean water passages. Cylinder Heads are supplied fully machined, pressure tested and assembled with valve seat inserts, valve guides and yoke guides.

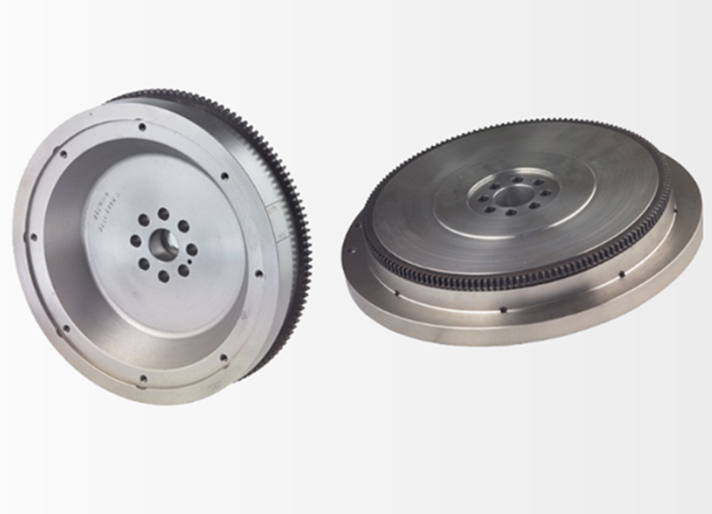

A critical disk-type part of an engine made from cast iron and spheroidized graphite iron through a permanent tooling process. All flywheels are made by using a vertical centrifugal machine to maintain the consistency of casting integrity and limiting the imbalance to less than one gram. In fact, the motion and timing of the engine is given by a flywheel. Flywheels are made from cast iron grades FG 20 to FG 30 and ductile iron

At Cooper Corporation, we are one of the leading flywheel manufacturing companies. We manufacture flywheels from quality materials according to customer specifications. We use state-of-the-art balancing techniques and devices to ensure quality, durability and seamless performance of every product, making our products highly dependable.

Aluminum parts are manufactured with processes such as gravity die casting, low pressure die casting or high pressure die casting. The process is decided based on the volume and criticality of the component.

We are well-equipped with the facilities needed for all the operations mentioned above, making us one of the best aluminum parts manufacturers in the country

Anti-polishing ring is manufactured using the centrifugal process. It fits in the inner groove of the cylinder liner and performs the crucial role of removing the carbon deposited on the piston, to enhance the performance of an engine.

These are made from cast iron grade FG20 to FG55 and machined on the special purpose machines.

Valve seat inserts are super alloyed cylindrical parts with high resistance to heat, and wear & tear. Mechanical properties and strength of the inserts are very high and are usually made in two types: inlet & exhaust. These fit into the cylinder head’s parent bore, while the valve is fitted into the seat inserts. The seat angle is the most critical parameter of the valve seat insert and is manufactured with high precision machines and toolings.

These are made from cast iron grade FG20 to FG55 and machined on the special purpose machines. Designed to suit a wide range of applications, Cooper Corporation’s valve seat inserts are manufactured with the necessary tolerance and high-quality levels to allow installation directly into the cylinder head guide bore without any additional work.

All valve seat inserts are centrifugally cast on Casting Machines. The centrifugal process assures that the castings are sound and will pass the radiographic examination.