Centrifugal Casting

Our expertise in centrifugal castings is supported by an ongoing technical tie-up with a leading European supplier of centrifugal casting equipment. We currently have ten of the thirty carousel casting machines available worldwide.

The centrifugal casting process ensures that the casting is free from any internal defects, as all the impurities are collected in the ID which is then machine cleaned.

Sand Casting

The process starts with a 3D model prepared in CAD which is then used to manufacture the necessary patterns and core boxes via CAM on CNC machining centers.

The plant is equipped with an imported Omega moulding line with a computer controlled mixer, compaction table and sand reclamation plant. After the moulds are prepared they are coated with a refractory, dried in infra-red ovens and then assembled with cores prior to pouring. Quality control checks are performed throughout the casting process from screening the raw material for stability to the concentration of alloy melted in the electric furnaces, to the final pouring temperature.

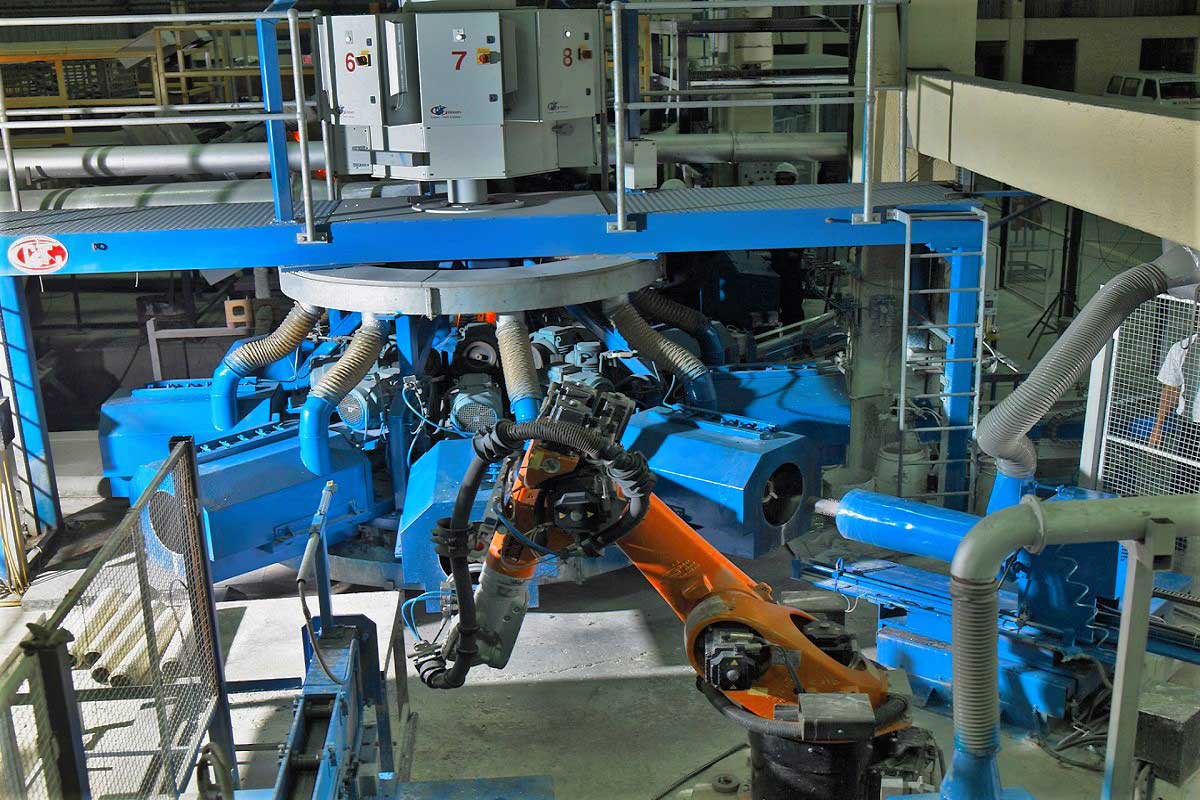

CNC and Robotic Machining Lines

At Cooper we use primarily CNC machines assisted by robots for machining all of our products. The state-of-the-art machines most of which are imported give us high levels of process control in maintaining the critical dimensions and geometry of the products.

Our skilled workforce monitors the robotic lines and SPC is widely used throughout the plants.

Crankshafts Machining

We machine crankshafts from single throw to six throw in lengths from 150mm to 1800mm in a diverse range for engines and compressors. The crankshaft division is equipped with CNC Crankshaft grinding machines accompanied by milling and drilling facilities

All crankshafts are dynamically balanced and 100% checked for cracks using sophisticated crack detection equipment.

Engineering

The manufacturing process at Cooper Corporation is ably supported by the engineering division, which designs all the dies, fixtures and tooling. All parts are designed jointly by the engineering and manufacturing divisions - that are located at the same site. Most of the tooling is produced, maintained and calibrated in-house, while only critical inspection gauges are manufactured and calibrated by other manufacturers.